SPOILER ALERT!

Batch Pasteurizers Is A Great Addition To Any Kind Of Food Procedure

Created by-Boyette Hebert

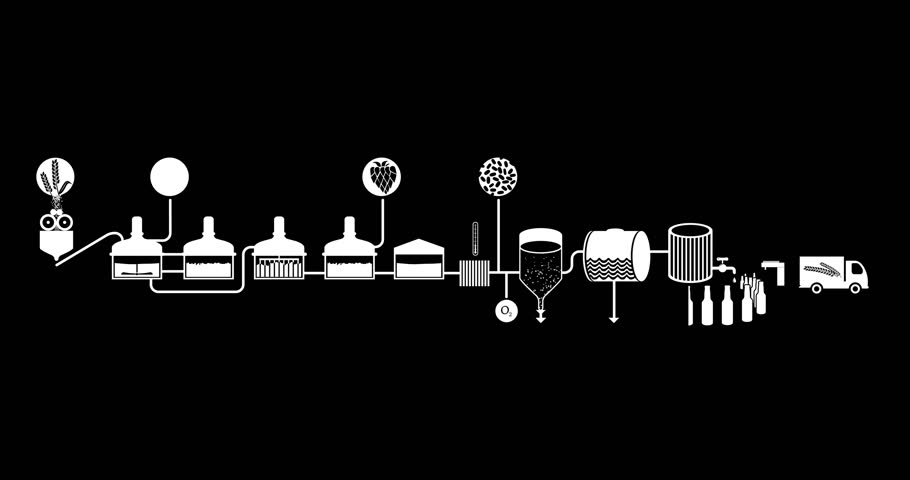

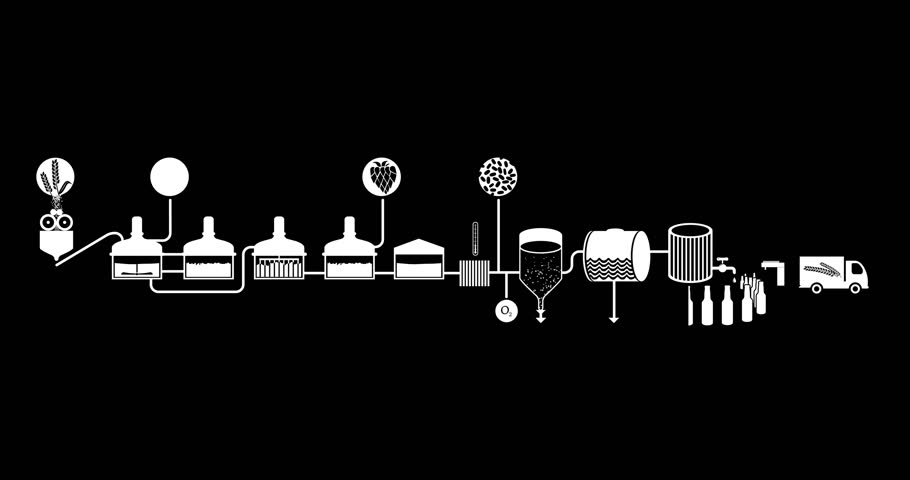

Tunnel Pasteurizers are used to promote the growth of microbes and also to enhance the top quality and purity of fermented foods. They have been around since the earliest methods of pasteurization were produced, as well as they have developed in addition to the various strategies of fermenting foods. Batch Pasteurizers and also Repair Work Refurbish Pasteurizers are typically used together to accelerate the Fermentation procedure as well as to shield the product from contamination as it is transferred from raw materials to the ended up products.

https://www.foodsafetynews.com/2011/05/meat-processors-file-petition-for-meat-poultry-pasteurization/ , sometimes called procedure of maceration, is the conversion of raw food product to an item where the procedure causes changes that advertise development of microbes as well as motivate growth of flavor. Completion result is an item that is thought about to be pure, although not always. In the starting the objective is to create something that has the greatest feasible dietary worth. Later on the objective is to produce foodstuffs that are both tasty and interesting. There are four actions associated with the whole process.

First, the food is placed in a container with a tap put for air. Second, the food is heated up to about 160 levels Fahrenheit or more using a burner or cooktop. The burner or oven is often outfitted with an air flow system to compel cool air into the container. This 2nd process seals in the flavor and extends the service life of the product.

https://drive.google.com/drive/folders/1uKlz2ZjKK6Ph8-u4wdehmV6numdW4yj8?usp=drive_open are utilized as key fermentation components, yet they can additionally be made use of as additional fermentation components. The distinction between key and secondary fermentation is the technique of including the society. Batch pasteurizers with the option of key or secondary fermentation are a terrific investment for any person thinking about making their very own home pasteurizers. When making use of Batch pasteurizers to advertise second fermentation, you make use of an energetic ingredient like S. cerevisiae, which is commonly made use of in the pet food market.

Batch pasteurizers made use of this way are called "Tunnel storages". Batch storages are designed to ferment food in big sets. They benefit from the natural process of food batchning by sluggish and gentle conditioning of grains and other components in secondary fermentation vessels. These vessels are usually referred to as "fermenters". They can be made from steel or timber, depending on the fermenting demands of the business.

Tip 3 entails the heating of the raw products to the wanted temperature. This makes certain that the item is at the correct fermentation temperature level before it is packaged. This step is very important because it makes sure that microorganisms do not grow after the food is packaged. Most of the very best pasteurizers on the market today utilize a direct-pasteurization procedure.

The last action of the process is the conditioning of the item. There are two main methods to problem food using these kinds of pasteurizers. Straight pasteurizing needs no more conditioning of the item. Indirect pasteurizers require a container to be loaded with the fermented item.

Tunnel pasteurizers will make your fermentation products even more scrumptious and also have a longer service life. They likewise will certainly maintain foods fresher much longer. Food can be conditioned for any kind of number of months, relying on the item and also the manufacturer's dish. Sterilizing is a simple and also efficient process for making the most of the flavor of fermented food.

To utilize Tunnel pasteurizers successfully, you must have a reliable container for storing and after that utilizing the completed item. These things must be classified with the Batch number, the name of the business (if different from the brand utilized to make the pasteurizer), and the temperature at which the item was sterilized. Make sure that there are no fumes or condensation marks from the initial manufacture procedure. You should have the ability to pour the contents of the Batch into the container without fear of the food becoming polluted. Food ought to be cooked prior to serving.

Batch pasteurizers are offered in lots of shapes and sizes, depending upon just how much food is being created at once. Some Batch equipments are dual-purpose and also will certainly sterilize and also cool various foods at the same time. Various other Tunnel devices have added ability for continual manufacturing while still retaining a smaller sized footprint. It depends on you to pick the suitable Tunnel device for your operation.

A set pasteurizer is a necessary tool in any type of food processing operation. These units enable a secure as well as controlled warm handling of foods during any type of phase of the production process. They use an affordable as well as safe ways of refining food at heats in an effective and also prompt manner.

Tunnel Pasteurizers are used to promote the growth of microbes and also to enhance the top quality and purity of fermented foods. They have been around since the earliest methods of pasteurization were produced, as well as they have developed in addition to the various strategies of fermenting foods. Batch Pasteurizers and also Repair Work Refurbish Pasteurizers are typically used together to accelerate the Fermentation procedure as well as to shield the product from contamination as it is transferred from raw materials to the ended up products.

https://www.foodsafetynews.com/2011/05/meat-processors-file-petition-for-meat-poultry-pasteurization/ , sometimes called procedure of maceration, is the conversion of raw food product to an item where the procedure causes changes that advertise development of microbes as well as motivate growth of flavor. Completion result is an item that is thought about to be pure, although not always. In the starting the objective is to create something that has the greatest feasible dietary worth. Later on the objective is to produce foodstuffs that are both tasty and interesting. There are four actions associated with the whole process.

First, the food is placed in a container with a tap put for air. Second, the food is heated up to about 160 levels Fahrenheit or more using a burner or cooktop. The burner or oven is often outfitted with an air flow system to compel cool air into the container. This 2nd process seals in the flavor and extends the service life of the product.

https://drive.google.com/drive/folders/1uKlz2ZjKK6Ph8-u4wdehmV6numdW4yj8?usp=drive_open are utilized as key fermentation components, yet they can additionally be made use of as additional fermentation components. The distinction between key and secondary fermentation is the technique of including the society. Batch pasteurizers with the option of key or secondary fermentation are a terrific investment for any person thinking about making their very own home pasteurizers. When making use of Batch pasteurizers to advertise second fermentation, you make use of an energetic ingredient like S. cerevisiae, which is commonly made use of in the pet food market.

Batch pasteurizers made use of this way are called "Tunnel storages". Batch storages are designed to ferment food in big sets. They benefit from the natural process of food batchning by sluggish and gentle conditioning of grains and other components in secondary fermentation vessels. These vessels are usually referred to as "fermenters". They can be made from steel or timber, depending on the fermenting demands of the business.

Tip 3 entails the heating of the raw products to the wanted temperature. This makes certain that the item is at the correct fermentation temperature level before it is packaged. This step is very important because it makes sure that microorganisms do not grow after the food is packaged. Most of the very best pasteurizers on the market today utilize a direct-pasteurization procedure.

The last action of the process is the conditioning of the item. There are two main methods to problem food using these kinds of pasteurizers. Straight pasteurizing needs no more conditioning of the item. Indirect pasteurizers require a container to be loaded with the fermented item.

Tunnel pasteurizers will make your fermentation products even more scrumptious and also have a longer service life. They likewise will certainly maintain foods fresher much longer. Food can be conditioned for any kind of number of months, relying on the item and also the manufacturer's dish. Sterilizing is a simple and also efficient process for making the most of the flavor of fermented food.

To utilize Tunnel pasteurizers successfully, you must have a reliable container for storing and after that utilizing the completed item. These things must be classified with the Batch number, the name of the business (if different from the brand utilized to make the pasteurizer), and the temperature at which the item was sterilized. Make sure that there are no fumes or condensation marks from the initial manufacture procedure. You should have the ability to pour the contents of the Batch into the container without fear of the food becoming polluted. Food ought to be cooked prior to serving.

Batch pasteurizers are offered in lots of shapes and sizes, depending upon just how much food is being created at once. Some Batch equipments are dual-purpose and also will certainly sterilize and also cool various foods at the same time. Various other Tunnel devices have added ability for continual manufacturing while still retaining a smaller sized footprint. It depends on you to pick the suitable Tunnel device for your operation.

A set pasteurizer is a necessary tool in any type of food processing operation. These units enable a secure as well as controlled warm handling of foods during any type of phase of the production process. They use an affordable as well as safe ways of refining food at heats in an effective and also prompt manner.